With today’s need for electronic equipment, manufacturers are realizing that in order to prosper—and in some cases to survive—they may have to export to global markets. When designing for global markets, a number of factors are involved, such as being able to provide equipment that is easily adaptable to the needs of the consumer, without any reconfiguration on their part.

One of the main considerations is to ensure the end-user has the correct means of connecting to their local mains supply. It’s also important to follow standards and country-specific regulations. Choosing the right components in the product design is essential as is identifying them in ways that others can understand.

Sometimes electrical terminology can be confusing because different people use different terms to mean the same product. For example, words that describe the means of connecting electrical equipment to a power source may be called a detachable or non-detachable cord, an appliance cord, a cable, a cable assembly, an interconnection, or a power supply, to name a few. They may also be called a power cord, a cord set, a jumper cord, and a connector power cord.

Following are definitions of products which are used at Interpower: power cord, connector power cord, cord set, and jumper cord set.

Power Cords

Power Cord

A power cord consists of cable with a country-specific plug (molded or hand-wired) on one end and exposed conductor wires, terminated conductors, or blunt/flush cut conductors on the other end. A power cord is used to connect the equipment directly to the power mains.

Connector Power Cord

A connector power cord has an IEC 60320 or country-specific connector (molded or hand-wired) on one end of the cable with the opposite end being exposed conductor wires, terminated conductors, or blunt/flush conductors.

Cord Sets

Cord Set

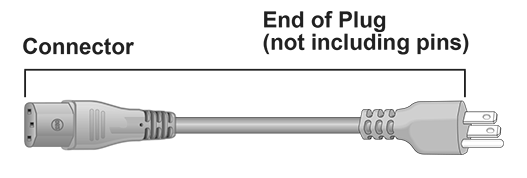

A cord set consists of cable with a country-specific plug (molded or hand-wired) on one end and an IEC 60320 connector or country-specific connector (molded or hand wired) on the other end. It is meant for connecting equipment directly to the mains supply.

Jumper Cord Set (or Accessory Cord Set)

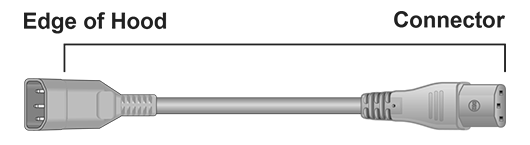

A jumper cord set has a connection device on both ends of the cable instead of just the plug end. A jumper cord set includes an IEC 60320 plug connector and an IEC 60320 connector and transfers power from a primary piece of equipment to an accessory or peripheral piece of equipment.

Choosing a Power Cord or Cord Set

The selection of the appropriate power cord or cord set is an important step for equipment designers to ensure that their product may be used worldwide. Choosing a cord usually involves four steps:

- Identify the Correct Plug for the Country of Export

The first choice concerns the plug pattern for the country of export. As there are a number of plug patterns used throughout the world, determining the correct one is essential. One guide to assist in this is Interpower’s Guide to Worldwide Plug/Socket Patterns & Power Mains (Single-Phase). “When deciding on the correct plug pattern, keep in mind that while some look similar that does not mean it is the right cord for the equipment. For example, the North American and Japanese Class I plugs look alike. However, North American cords do not carry the Japanese approval symbol and therefore should not be exported for use in Japan. The same can be said for Japanese cords which will not carry North American approval. Another example is the similarities in appearance in the Australian, Argentinean, and Chinese plug patterns, but again there are important differences between the three,” explained Ron Barnett, Product Development Manager at Interpower.

- Determine the Rating of the Power Cord or Cord set

In order to choose the correct power cord or cord set, it’s crucial to know the amperage and voltage rating that is required for the equipment being exported. “Higher or lower amperage can mean a different plug pattern, even in the same country. Amperage requirements also affect the cable size. Note that North America has a different voltage, amperage, and frequency compared to much of the rest of the world,” he said. The Guide to Worldwide Plug/Socket Patterns & Power Mains (Single-Phase) also gives information on the world’s voltage and frequency requirements.

- Choose the Correct Cable

“Again the country of export for the product matters when choosing the cable,” Ron said. “There are differences between North American and international cable and they are not interchangeable. North American cable cannot be used in countries where international cable standards are in place and vice-versa. For example, removing a North American plug from a cord set made with North American cable and replacing it with a Continental European plug will not make the cord set acceptable for Europe.”

- Choose the Correct Connector, if Utilizing a Cord Set

Choices for a connector may include an IEC 60320 connector or an inline country-specific socket. “An advantage of using IEC 60320 components is that they can assist in making a product globally accessible,” he said. “For example, an IEC 60320 connector can be attached to a detachable cord set with a country-specific plug. The connector will provide the power to the equipment by connecting with an IEC 60320 inlet in the equipment. The use of IEC 60320 components designed into a product allows the same equipment to be used in a variety of markets.”

A power cord or cord set is rated by the “weakest link.” This means that the plug, cable, and connector are considered as individual components and the one with the lowest rating determines the rating for the entire assembly. For example, a cord set with a 15A plug on 13A cable with a 10A connector will have an overall rating of 10A.

Measuring Cord Lengths

Depending on the application, cable length in a power cord or cord set is a choice for the designer. Interpower offers standard length power cords and cords sets, as well as specialized lengths. When measuring all power cords and cord sets, Interpower uses a standard method of measurement.

When manufacturing power cords and cord sets, Interpower follows North American and international standards, along with minimum and maximum lengths per country regulations and/or standards. It should be noted that there are application limits that need to be considered. For example, cords over 50 feet in the United States and Canada will have the amperage rating derated. For international applications, the derating depends on the application and the cable used in the assembly.

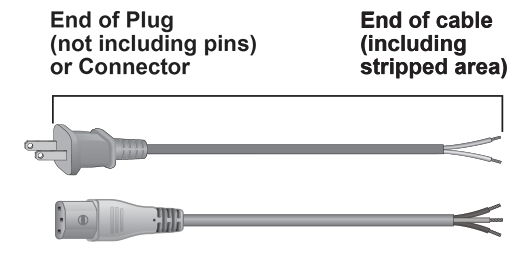

Interpower measures its cord sets from the face of the connector to the face of the plug, not including the pins. Interpower uses this method for all cord sets.

When using a hooded male plug, the measurement will be from the edge of the hood.

Interpower measures its power cords from the face of the connector or plug, not including the pins, to the end of the cable. Interpower uses this method for all power cords.

The Interpower standard tolerances include the following:

| Length | Standard Tolerance |

|---|---|

| 0–2.99 ft. (0–913mm) | +/- 1 in. (25mm) |

| 3–5.99 ft. (914–1827mm) | +/- 2 in. (51mm) |

| 6–11.99 ft. (1828–3656mm) | +/- 3 in. (76mm) |

| 12–19.99 ft. (3657–6095mm) | +/- 4 in (102mm) |

| 20–49.9 ft. (6096–15210 mm) | +/- 6 in (152mm) |

| 50+ (15240+ mm) | +/- 12 in (305mm) |

Testing at Interpower

Interpower manufactures power cords and cord sets for a number of different countries and regions. “Cords that are manufactured by Interpower are 100% tested,” Ron explained. “The electrical testing includes Hipot, continuity, and pull. One Hipot test checks for shorts between the ground and line and the ground and neutral. A second Hipot test checks for shorts between the line and neutral wires. The purpose of the continuity test is to confirm the assembly is wired correctly and there are no breaks in the wire from one end to the other. The pull test ensures that a quality crimp exists.” All plugs, connectors, and cable are also visually inspected for surface quality, molding flash, markings, etc.

Additional Resources

For more information on power cords and cord sets, see the Featured Product page. To assist in determining cord specifications per a specific country or region, see North American Power Cords and Cord Sets and International Power Cords and Cord Sets. To identify which plug patterns are used in specific countries, see the Guide to Worldwide Plug/Socket Patterns & Power Mains (Single-Phase).

Interpower offers free technical support and value-added services. For further assistance, please see Interpower’s contact information below.