More Information on Power Entry Modules

Looking for Hospital-Grade Information? Click here

Modules

Simplifying the power entry element in an electrical or electronic product with a module can help make the assembly easier and may benefit a company in product design.

Benefits

A module is a device that can combine multiple functions into a single unit to control power entry. There are several reasons to choose a module over individual components. The IEC 60320 inlet is the most common means of connecting a detachable cable assembly to equipment. Once the cable assembly is connected, other components are necessary to control the electrical power to protect the equipment and the user. These components can create clutter on the equipment and a wiring problem on the inside. To help simplify the problem, a module can include multiple power entry functions in one compact unit, while providing various forms of protection and control. Modules are ideal for use in a variety of applications, including information technology and medical equipment.

Even though these functions are available as individual components, when properly specified for a particular application, the benefits of a module may include increased user safety, lowered component management and costs, reduced assembly labor, and saved panel space.

Increased User Safety

The risk of accidents may be reduced when using a module. The design of most modules makes it necessary to remove the power cord assembly from the unit prior to making any changes, like fuse replacement and/or voltage selection. Interlocking the power entry connector with access to other module functions reduces the probability of accidental shock by the user.

Lowered Component Management and Costs

While modules rarely save money when compared to direct material costs, the savings in assembly, engineering, and materials handling time may more than cover the additional costs. Decreasing the number of components used in equipment can help reduce time in testing and recording documentation for component and agency approvals. Materials, handling, and purchasing time are also reduced through reduction in inventory.

Reduced Assembly Labor

Power entry modules can reduce installation labor costs. The combination of several components into one package reduces the number of components that must be handled. Assembly labor costs may be reduced due to less internal connections that need to be made.

Saved Panel Space

Power entry modules combine several components into one panel mounting system, saving panel space. This reduces the mounting hold size, thus saving valuable space on the mounting surface.

|

|

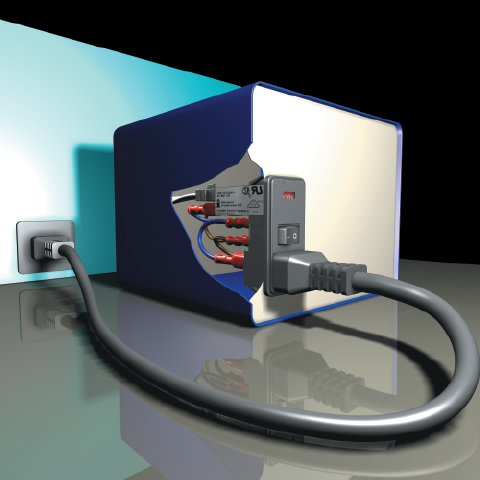

| Interpower power entry module on equipment saves panel space | Components mounted individually on equipment panel use more panel space |

Module Functions and Components

When selecting a module, the desired functions need to be determined. A module may have from two to five functions. These include: power inlet or outlet, switch, circuit protection, filter, and/or voltage selector.

|

|

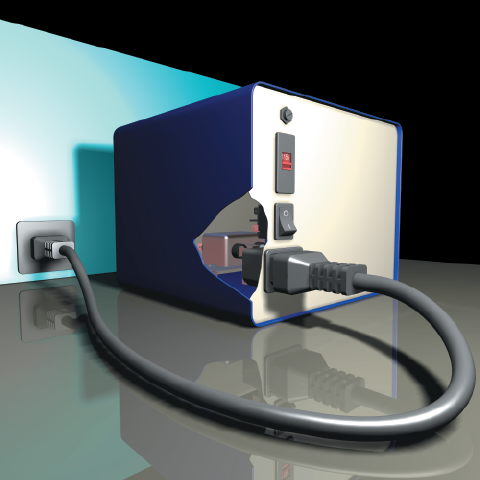

| This is one example of a module. There are different styles and various combinations of functions that can be included in a module. |

Interpower’s modules may have from two to five functions. These functions include: inlet, outlet, switch, circuit protection, filter, and/or voltage selector.

Inlet

The power inlet is responsible for bringing electricity into the unit via connection with a detachable cord set. The most common inlet is the IEC 60320 C14, although other IEC 60320 style inlets, such as the C6, C8, and C20, are occasionally offered by some manufacturers. Modules using the C14 inlet are typically specified for applications 10A and below.

Outlet

An outlet is an IEC 60320 connection device that provides access to electricity from a power source. Outlets range from 10-20 amps.

Switch

The switch is used to turn the power on (“I”) and off (“O”) from the module to the rest of the unit. It is important to check the appropriate equipment standard for instructions regarding the position of “on” as some may require the “I” to be installed in a vertical position.

Rocker style switches are the choice of module manufacturers. Some modules use a double-pole, single-throw switch and others use single-pole, single-throw switch. While unlighted switches are the most common, they can be either lighted or unlighted.

|

|

| Switch for horizontal mount applications | Switch for vertical mount applications |

Circuit Protection

Circuit protection takes the form of a circuit breaker or a fuse. Both provide current protection to the equipment, reducing the possibility that a short circuit can damage the equipment or harm the user.

When a product is being designed for multiple markets, a fuse has an advantage over a circuit breaker in that it’s more cost effective and it’s easier to modify. Fuses are less expensive than circuit breakers. In addition, this allows the customer to change the size of the fuse to match the application, resulting in them being able to use the single module in multiple applications. Circuit breakers installed in modules can limit them to certain applications, based on the size/rating of the breaker. Fuses also have different clearing characteristics (fast-acting, slow blow, etc.) that allow equipment manufacturers to fine tune for their applications. This would not be possible with a pre-installed circuit breaker.

Fuse holders and carriers are commonly built into modules so the fuses can be installed to provide circuit protection against abnormal surges and overloads. When determining the amp rating of the fuse, it should not exceed the overall rating of the module.

Most modules with fusing capability must be specified as needing either single-fuse or double-fuse capabilities depending on the applicational needs. Some have the ability to be configured either way.

Modules do not come with fuses in them. They must be ordered separately. Fuses cannot be included in modules for liability reasons. It is the equipment manufacturer’s responsibility to determine the best fuse for the application and order it for optimal performance.

Fuses come in two different sizes. In North America, the standard size is ¼ x 1¼–inch while the common size in international markets is 5 x 20mm. The smaller international fuse is starting to become more prevalent in North America. Some modules can accept both sizes of fuses, while other modules are designed to only accept one specific size fuse. It’s important to check fuse size specifications of any module being considered in order to choose the best one for a specific application.

Filter

A filter plays an important part in equipment design, especially in high frequency and medical equipment applications. It can remove specified frequencies (RFI/EMI) that can affect equipment operation. A filter helps to provide clean electricity to the equipment.

The circuit components of filters are inductors and capacitors. The difference between a standard filter and a medical-grade filter is that capacitors between the circuit conductors have been removed in the medical versions in order to decrease leakage current values. This is important for equipment where leakage current values are tightly controlled by safety standards in order to ensure patient safety.

Interpower filtered power entry modules are available with or without a metal shield, typically specified in high frequency applications. An RFI/EMI filter is an electrical circuit that is designed to remove electromagnetic and radio frequency interference (noise) from the equipment. This prevents malfunctions due to interference and also prevents the equipment from radiating noise, which might interfere with other equipment.

Whenever specifying a module with a filter, it is necessary for a company to obtain samples to test with one’s application to ensure they will perform as desired. This is because filter performance specifications are based on an industry standard 50 ohm test circuit and certain aspects of an application’s design may alter the way a filter performs when the circuits are connected.

Voltage Selector

Voltage selection allows equipment to be designed and manufactured to operate on approximately 115 or 230VAC. A voltage selector changes voltage by changing connections on the transformer. By changing the selection, this allows the user to define the correct input voltage. Voltage selection changes are made by removing the fuse holder and rotating it. It is important to note that the voltage selector is a specialized switch which works in conjunction with a transformer that is designed into the customer’s equipment. The transformer is not part of the actual module, but it creates alternate circuit paths for the voltage selection process. If the customer has a switched mode power supply (which is any power supply between 90-264V), then a voltage selector is not needed.

Hospital-Grade Power Entry Modules

Hospital-grade equipment must meet special requirements. These requirements place special significance on fusing and filtering when selecting components used in medical equipment. Patient-connected medical equipment can be subjected to low-leakage current requirements. The use of a low-leakage filter in the 5µA range at 250VAC is desirable. In addition, fusing of both line and neutral may be required (i.e. double fusing). For more information, see Hospital-Grade Power Entry Modules and “More Information on Hospital-Grade Products” on the Interpower website.

Additional Resources

Interpower offers free technical support. For more information to determine which kind of module is best for a specific product design, contact Customer Service. See the complete line of modules and fuses and fuse holders available at Interpower. See also the modules highlighted on the Featured Product page.