Strain reliefs serve several purposes. First of all, some strain reliefs provide a liquid-tight seal on the power cord entry into the equipment. This prevents moisture from entering the interior of the equipment and causing potential damage to components and circuitry. Secondly, strain reliefs provide extra protection to power cords by protecting the cord from coming into contact with sharp edges on the chassis and over-bending. This protection helps extend cord life. Lastly, they reinforce the cord connection to your equipment. Many strain reliefs anchor the cord in a stationary position that prevent stress, such as twisting or pulling on the conductors, from reaching the wire connections inside the equipment, which could result in broken wires and the need for frequent cord replacement.

Strain reliefs serve several purposes. First of all, some strain reliefs provide a liquid-tight seal on the power cord entry into the equipment. This prevents moisture from entering the interior of the equipment and causing potential damage to components and circuitry. Secondly, strain reliefs provide extra protection to power cords by protecting the cord from coming into contact with sharp edges on the chassis and over-bending. This protection helps extend cord life. Lastly, they reinforce the cord connection to your equipment. Many strain reliefs anchor the cord in a stationary position that prevent stress, such as twisting or pulling on the conductors, from reaching the wire connections inside the equipment, which could result in broken wires and the need for frequent cord replacement.

There are several things to think about when choosing a strain relief for your equipment. In this article we will look at six attributes of a strain relief to consider in order to choose the correct part.The first thing to consider when choosing a strain relief is the material used. Two popular choices are nylon and nickel plated brass. Choosing a brass strain relief will be higher in cost, and may be better suited for high end equipment where nylon strain reliefs may look “cheap.” Nylon strain reliefs, in most instances, have the same performance as brass, but with less cost. Other options available are PVFD (polyvinylidene fluoride), aluminum, and stainless steel.

Secondly, you should determine the style of strain relief you need for your application. Dome style strain reliefs are the most common and are designed to protect the wire entering the equipment. They help to secure the wire connection to the equipment and provide longer life to the cord by preventing it from rubbing against a rough or sharp edge where the cord passes through the equipment panel. Flex style strain reliefs offer flexible bend protection to the cord entering the equipment. They are designed to eliminate the possibility of the power cord kinking at the point where the cord enters the equipment.

Thirdly, along with the basic style, you should determine the body style needed. Strain reliefs can enter into the equipment with a straight body style, or a 90 degree body style. Dome style strain reliefs also have options for multi-cable entry, flat cable, mini strain reliefs for the smallest cable sizes, and EMI to protect from electromagnetic interference.

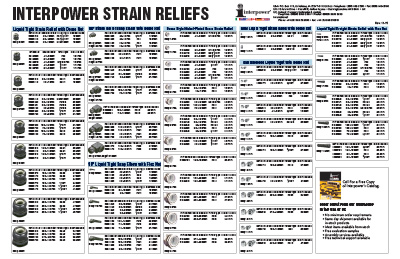

The fourth thing to consider in order to determine the correct strain relief is the thread type and size. There are three thread types used worldwide. The first is National Pipe Thread (NPT). The NPT thread type is the North American standard, and therefore is most commonly used for North American equipment. The second thread type is Panzer Gerwinde (PG). The PG thread type is a German standard used throughout Europe and is sometimes referred to as metric; however these threads are not truly metric as PG threads have a different angle and depth. The third thread type is Metric. The Metric thread type is the international standard and can be used worldwide. Each of the three thread types has their own standard size scale, as shown in the charts below.

The fifth option to consider is your mounting hole. The mounting threads of the strain relief can be threaded directly into the panel of the equipment, or the strain relief can be eased through a clearance hole in the panel and fitted with a locking nut. Match the diameter of your mounting hole to the Major Diameter Inches (see above charts) to determine the size of strain relief you need.Finally, in order to choose the correct strain relief, you should consider the cable you are using. You should know the diameter of your cable. When looking at the correct style strain relief, find the ones that have the correct thread size or mounting hole size. Then look at the cable diameter specification range and choose the one that has the best fit. Ideally, the cable diameter should be towards the top end of the cable range for the strain relief chosen. If this is not possible, use the one with the best fit.Considering these six attributes, you can easily determine the correct strain relief for your application. For more information, you can view our Strain Reliefs webcast.

The fifth option to consider is your mounting hole. The mounting threads of the strain relief can be threaded directly into the panel of the equipment, or the strain relief can be eased through a clearance hole in the panel and fitted with a locking nut. Match the diameter of your mounting hole to the Major Diameter Inches (see above charts) to determine the size of strain relief you need.Finally, in order to choose the correct strain relief, you should consider the cable you are using. You should know the diameter of your cable. When looking at the correct style strain relief, find the ones that have the correct thread size or mounting hole size. Then look at the cable diameter specification range and choose the one that has the best fit. Ideally, the cable diameter should be towards the top end of the cable range for the strain relief chosen. If this is not possible, use the one with the best fit.Considering these six attributes, you can easily determine the correct strain relief for your application. For more information, you can view our Strain Reliefs webcast.

Provide Bend Protection to Your Cords

Interpower Corporation strain reliefs provide protection to the wires and cable from stress and damage as they run through the panel of the equipment. Interpower Corporation carries metric strain reliefs, along with NPT and PG thread types. We offer a variety of styles including nylon or nickel-plated brass dome-nut, nylon flex-style, and 90 degree angled strain reliefs. RoHs strain reliefs are available as well. View our line of strain reliefs to choose the best product for your application. We have no minimum order requirements, so you only purchase what you need. Order online at www.interpower.com.

Interpower Corporation strain reliefs provide protection to the wires and cable from stress and damage as they run through the panel of the equipment. Interpower Corporation carries metric strain reliefs, along with NPT and PG thread types. We offer a variety of styles including nylon or nickel-plated brass dome-nut, nylon flex-style, and 90 degree angled strain reliefs. RoHs strain reliefs are available as well. View our line of strain reliefs to choose the best product for your application. We have no minimum order requirements, so you only purchase what you need. Order online at www.interpower.com.

Free! Interpower Strain Reliefs Wall Chart

Here is your chance to request your free copy of our Interpower Strain Reliefs Wall Chart. This handy chart lists specifications for NPT, PG, and Metric strain reliefs along with Interpower part numbers. Click on the chart to download your copy or visit our mailing list and enter “Strain Reliefs” in the title to request a copy to be sent to you.