Building Equipment for Global Markets with Accessory Power

Incorporating an accessory power distribution system into an electrical product design can enhance that product’s marketability.

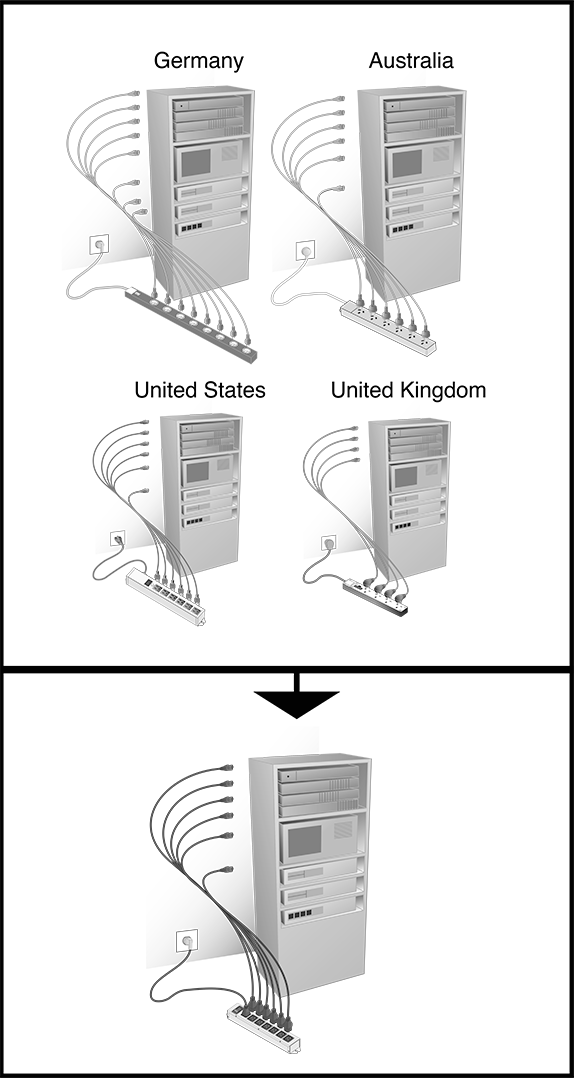

Accessory power defines power connections to peripheral equipment from a central system. This illustration shows a typical accessory power system using IEC interconnection components, with a country-specific cord set (in this example, a Continental European cord set) that connects to a wall socket. Country-specific plugs and sockets are not needed for accessory power connections.

Advantages of Accessory Power

There are two main advantages for equipment designers to use accessory power.

- One advantage is to specify one plug and socket configuration that is accepted for use throughout the world.

- Another advantage is that accessory power distribution systems are commonly used to distribute and control power to peripheral equipment through a central system.

“Accessory power is specifying one plug and socket configuration that is accepted globally for connections between equipment systems. A country-specific mains connection is needed only for the primary power supply connections,” explained Dan Ford, Technical Support Specialist at Interpower. “This makes it easier to design and build equipment that can be accepted worldwide. The IEC interconnection system is generally accepted for use throughout the world. By using a plug and socket configuration that is accepted globally, it can allow the equipment to be more marketable.”

Using an accessory power distribution system is also a key advantage for equipment systems that use multiple electrical and electronic devices, such as industrial, information technology, medical, laboratory, or food production. “A key to success for a company trying to compete worldwide is to offer products that are easily adapted to the needs of the global markets without requiring reconfiguration by the user,” Ford said.

Components Used in Accessory Power

In order to design products that do not require reconfiguration by the user, one way is to incorporate accessory power distribution components that are based on the IEC 60320 standard.

The key components can include: a power inlet, an outlet, a connector, a plug connector, and a jumper cord.

Power Inlet

Power Inlet

A component common to the input power and accessory power distribution is the AC power inlet. It is typically either snap-mount or screw-mount.

Outlet

Outlet

The IEC outlet can be an important part of the equipment. It is typically either snap-mount or screw-mount and may be integrated with an EMI shield and filter to minimize radiated and conducted noise emissions. In applications where vibration or transportation of equipment could create unwanted power disconnections, consider the use of a connector lock.

Connector

Connector

The connector is commonly molded on or assembled on to flexible cable.

Plug Connector

Plug Connector

The corresponding component to the outlet is the IEC plug connector, which is commonly molded or assembled on to flexible cable. This is the IEC plug equivalent to a country-specific plug.

Jumper Cord

Jumper Cord

A jumper cord is a combination of a connector and a plug connector on flexible cable. This is the IEC cord set equivalent to a country-specific cord set.

For a list of all of the IEC 60320 components, see IEC 60320 Appliance and Interconnection Couplers guide.

Accessory Power Strip

Accessory Power Strip

Another key component to the accessory power system is the Accessory Power Strip (APS). “At its core, this power strip incorporates the AC power inlet, with multiple AC power outlets, typically four, but as many as 20 outlets. Other features commonly included are power on/off switches, circuit breakers, supplementary overcurrent protector or fuse holders and fuses,” Ford said.

“It is important to note that overcurrent protection is for the entire power strip. A power strip with a 15A circuit breaker does not mean that each outlet can deliver 15A maximum each. It means that the entire power strip, whether four or 20 outlets, can deliver up to 15A across all outlets combined,” he emphasized.

This illustration shows how an accessory power distribution system can help contribute to a company’s success.

“At Interpower, we can make it easier to build equipment that can be sold worldwide because different components work together in one system. Instead of having to make five different systems to export to five different countries, a company can design one system and then add a cord set with a country-specific plug,” Ford said. “This allows the same system to be exported globally with cost-saving benefits.”

Additional Resources

For more information on accessor power offered by Interpower, see Accessory Power, the Featured Product page, and Interpower’s webcast on Accessory Power for Worldwide Markets.

Interpower offers free technical support. For further assistance, please see Interpower’s contact information below.