Interpower Plugs and Sockets—Meeting Electrical Needs

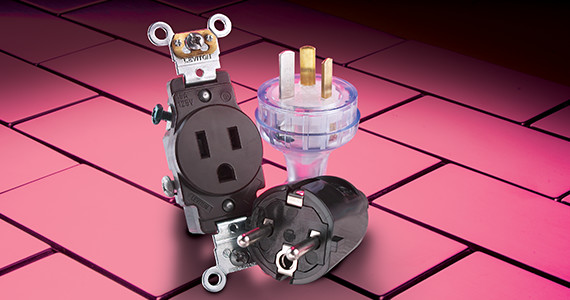

Plugs and sockets meet an electrical need. They are the components used to connect electrical equipment to a power supply without tools.

But as simple as that definition sounds, it needs to be noted that there are numerous plug patterns used throughout the world, making it anything but simple. When designing electrical or electronic equipment, the right plug and socket need to be specified to meet the requirements of the product. Because plug patterns vary greatly by country, it’s important to determine how to correctly and safely connect to the power supply.

For equipment to be connected to an AC (Alternating Current) supply, there are two choices: hard wiring which is making a direct connection to the electrical circuit or an electrical assembly, using a cord set or power cord that uses a national standard plug. Hard wiring takes a qualified electrician to connect/disconnect the equipment. The electrical assembly provides the user with a method of powering up the equipment correctly and safely by easily allowing the plug to be inserted into a mains socket.

When electricity was first introduced in the late 19th Century, it was mostly used for lighting purposes. When household appliances began to be invented in the early 20th Century, new ways of connecting to the power supply needed to be created. That resulted in individual countries developing their own style of plugs and sockets. There were early efforts dating before World War II to try to initiate one plug pattern globally, but the idea never caught on. Discussion in the 1950s regarding the standardization of one plug worldwide basically came too late, as many countries already had their own electrical connections in the homes and businesses and were not willing to change over to a new plug design.

Today, manufacturers designing for global markets need to be aware that there are many different plug patterns. They will need to determine which one is used in the country they will be exporting to.

Designing for Global Markets

It is important to determine the following about plugs and sockets when designing and building a product:

Ratings

A plug and socket have a maximum voltage and amperage rating. The ratings are determined by national and/or international standards. They are set for safety purposes and are often higher than the actual current measurement at use. For example, if a Continental European plug is rated for 16 amps at 250 volts, it is unlikely that there will be a constant current of 16A at 250V flowing through the electrical connection. European voltage is standardized at 230V. In the United States, the NEC (National Electrical Code) sets the standard for the common household use to be 120VAC.

Class I and Class II

Plugs and sockets can be rated for Class I or Class II applications. In a Class I application, the component must have the ability to provide grounding. In a Class II application, there is no grounding required.

Even though some electrical systems in developing countries may be ungrounded, it is not recommended to cut off the ground pin so that a plug can fit into a two-pole, ungrounded socket. This eliminates the safety ground connection and will cause the plug or socket to lose its approval. It is better to use a Class II plug on a power cord or cord set, than alter a Class I assembly.

Polarized Versus Non-Polarized

Polarized can have two meanings: electrical or pin. Electrical polarization means there is a standardized method of wiring the plug or socket to circuit wires. The circuit wires need to connect correctly to the line, neutral, and ground contact points on the plug and socket. The components mirror the electrical circuit. Pin polarization means there is a dedicated alignment of the pins—there is only one way of the plug fitting into the socket. Note: Even though a plug is pin polarized, it doesn’t necessarily mean it is also electrically polarized.

Approvals

It’s essential to include the correct plug and socket in the product design according to what is used in the country of export and to follow the specific standard (if there is one). In most countries, approval documentation is needed in order for the final product to be accepted into that country.

Additional Resources

Interpower offers a variety of international and North American plugs and sockets that are designed to meet electrical needs around the world. Resources that can assist in choosing the correct plug pattern include Interpower’s Guide to Worldwide Plug/Socket Patterns and on Interpower’s website—Power Cords and Cord Sets and Plugs and Sockets web pages. See also the Interpower Featured Product pages on Plugs and Sockets and Power Cords and Cord Sets.

Interpower offers free technical support. For further assistance, please see Interpower’s contact information below.