Secure Value by Testing Products in

Advance for Global Export

Does your global customer perceive your product as worthwhile and one that meets his/her requirements for value? For companies choosing to design and build products for worldwide markets, pre-testing of that product will be essential to ensure that value is secure.

When designing a product with global customers in mind, it is essential to know before it is shipped that the product will work in the country of choice. “The intended end use and destination of the product needs to be considered. The designer needs to keep in mind which safety standards need to be met per the specific country. Since customers expect a product to work when it is unpacked from the box, verifying in advance that a product will work in a global market can give a company a competitive advantage, along with enhancing customer relations,” explained Ron Barnett, Product Development Manager at Interpower.

Designing for a Global Market

The following considerations are highly recommended when designing for a global market.

Use the Correct Plug/Socket Standard

Currently, there are numerous plug and socket standards used throughout the world. A company needs to use the correct plug for the country of export. It is also advised to equip the product with the necessary cable and connectors so the customer will not have to modify the product before use, which could cause problems and possible loss of approvals.

Set the Product at the Correct Voltage and Frequency

It is advised to design the product so it is set at the correct voltage and frequency. Voltages vary around the world, so it’s important to know the voltage rating of where the product will be used.

Design the Product to Meet the Correct Standards

Make sure the product meets all applicable safety standards, according to the country where the product will be exported.

Test the Product During the Design Process

It is essential to test the product. By testing during the design process, the manufacturer can potentially save costly modifications that may occur after the product is in production, avoid possible failures or repairs, and hopefully avoid returns because the product doesn’t work properly in that country.

Test the Product Prior to Shipment

The product should be thoroughly tested at international voltages and frequencies, including a suggested 24-hour burn-in test before shipment. Pre-testing helps to ensure the product will work when it reaches the global customer.

Validation Testing

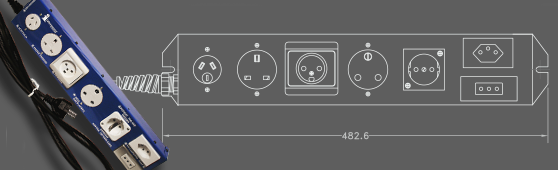

“Because validation testing helps to ensure that the product meets the intended needs of the end use customer, an International Socket Strip offered by Interpower can be used to test or burn-in electrical and electronic equipment that will be exported with international power cords and cord sets,” Ron said. “This allows testing of the equipment, complete with the power cord, in the same manner that the global customer will use it. It should be noted that the International Socket Strip does not change voltage or frequency.”

The International Socket Strip can be connected to a test bench or burn-in rack that has a source of 50Hz or 60Hz to deliver power to some of the most commonly used worldwide sockets. (If a source of 50Hz or 60Hz is not available, this is an example of when the International Socket Strip and the International Power Source can work together.) To test a product, the correct power cord needs to be installed into the product and connected to the proper socket. “The International Socket Strip enables designers to perform internal testing in a simplified manner using a single power strip which includes multiple country sockets,” Ron said. “This eliminates the need for multiple socket strips to perform in-house testing.”

Interpower offers three different models of the International Socket Strips. Each one incorporates the following sockets into each model: Continental Europe (16A), Denmark (16A), Italy (10A), India/South Africa (15A), Switzerland (10A), Australia (10A), and United Kingdom (13A). One of the models also includes a NEMA 5-15 socket.

Additional Resources

See the complete line of International Socket Strips available at Interpower, along with the Featured Product page.

Interpower offers free technical support. For further assistance, please see Interpower’s contact information below.