More Information on Cable

Cable completes the electrical circuit from the power source to the equipment. The end destination of the product will determine the type of cable that will need to be used.

Selecting the Correct Cable

When designing an electrical/electronic product that will be for sale in any part of the world, deciding on the type of cable is an important step in that process. To assist in selecting the correct cable, please consider the following questions.

Where is the End Destination for the Cable?

The market that the product will be sold in, such as North America, Europe, Asia, or South America, will determine the type of cable and approvals that are needed. For example, if the product is to be sold in the United States, then North American approved cable needs to be used. If it is in Germany, then it will need to be international approved cable. If the country is China, the selection will need to be Chinese approved cable.

What is the Application?

There are two factors to consider when determining the correct type of cable: how the product will be used and the environment it will be used in. The application will determine the outer jacket material recommended for the cable. For example, a household appliance that will be used indoors will likely have a different kind of cable than a hand tool meant to be used at an outdoor construction site.

Possible materials for cable include:

Thermoplastic

Thermoplastic can be softened through heating and hardened through cooling. It can be molded when heated and can retain its shape after it cools. Thermoplastic is the opposite of thermoset.

PVC

PVC is a common thermoplastic material for cable and conductor jackets and some molded plugs.

Thermoset

Thermoset uses a heating process called curing and once the plastic is cured, it cannot be changed but keeps its shape.

Rubber

Rubber is also a common material for cable. It is a thermoset-type material. While it may be more costly than thermoplastic cable, it tends to be more durable with high levels of water and abrasion resistance. Rubber is a good choice for outdoor applications.

Thermoplastic Elastomer

TPE is a material that has characteristics of rubber, as well as thermoplastic.

For indoor use, jacket material typically is PVC. For outdoor and/or industrial use, the jacket material may be rubber, TPE, or PVC. For outdoor use, it’s also important to determine what specific conditions the cable needs to be protected from, such as abrasion, water, oil, and/or sunlight.

What are the Power Needs?

The end destination for the product determines what the power needs will be. Different countries/regions have different amperage and voltage requirements. Knowing those requirements at the beginning of the design process is crucial. These factors will affect the size and type of the cable needed to supply safe electrical power.

For example, in North America, circuit voltage is usually 120V or 240V, using 15A for non-industrial needs. For industrial needs, typical requirements would be 120V, 120/208V or 120/240V using 20A or less. In the European market, non-industrial needs are usually 230V using 16A or less, whereas the industrial needs could be 230 or 400V using 32A or less.

North American and international cable standards dictate the ratings for different designated sizes. Because of the difference in ratings guidelines between the different standards, North American cable ratings do not necessarily match up with international cable rating standards.

What Temperature Will the Cable Be Subjected To?

Typical indoor room temperatures may range from 20°C to 30°C. Properly operating equipment may generate an additional 30°C, so cable for indoor applications is typically rated for at least 60°C. If the product is a heating appliance, consider using a rubber jacketed cable or a special heater type cable.

Outdoor/industrial ambient temperatures and equipment usually have higher extremes and therefore the cable may need to be rated from -50°C up to 105°C.

How Will the Cable Be Connected?

All electrical equipment needs some way of receiving power and the cable completes the electrical circuit from the power source to the equipment. It may be with a connector/inlet combination (detachable) or it may be hardwired with a strain relief/cable gland (non-detachable).

Comparing and Contrasting North American and International Cable

Two of the widely used types are North American and international approved cable. While the two cable types may be similar in appearance, there are a number of important differences.

Sizing

North American Cable

The sizing for North American cable is noted by AWG. The gauge uses an inverse relationship to the size, so the larger the number, the smaller the cable. For example, a small gauge North American cable with three conductors might be 3 x 18 AWG (or 18/3 AWG). A large gauge cable might be 3 x 10 AWG (10/3 AWG).

International Cable

International cable is sized in square millimeters. This measurement comes from the diameter taken from the circumference of a cross section of each conductor. The size is expressed in millimeter-squared (mm2). Size increments are designated within the standards and vary as the cable size increases.

Cable Types

North American Cable

There are a variety of North American cable types with letter designations indicating different kinds. The types of North American cable offered by Interpower include:

PVC Cable

- SJT—Junior hard service, thermoplastic-insulated conductors and jacket.

- SJTO—Same as SJT, but oil-resistant thermoplastic outer jacket.

- SJTOO- Same as SJTO but conductor insulation and jacket BOTH oil resistant.

- SJTOW—Same as SJTO except weather-resistant rated.

- SJTOOW- Same as SJTOW but conductor insulation and jacket BOTH oil resistant

- SJTW—Hard-usage thermoplastic or rubber-insulated conductors and overall thermoplastic jacket; weather-resistant for outdoor use.

- SVT—Thermoplastic-insulated vacuum cleaner cord, with or without third conductor for grounding purposes.

- SVTO- Same as SVT but oil-resistant thermoplastic outer jacket

- SVTOO- Same as SVTO but conductor insulation and jacket BOTH oil resistant

- SPT-2—Parallel jacketed thermoplastic cable with heavier construction than SPT-1.

- ST—Hard service cord with all thermoplastic construction.

- STO—Same as ST, but with oil-resistant thermoplastic outer jacket.

- STOO- Same as STO but conductor insulation and jacket BOTH oil resistant

- STOW—Same as STO, but weather-resistant rated.

- STOOW- Same as STOW but conductor insulation and jacket BOTH oil resistant

Thermoset Cable

- SO—Extra hard service cord, thermoset-insulated conductors and thermoset oil-resistant jacket.

- SOW—Same as SO except weather-resistant rated.

- SOOW—Same as SO except both conductor insulation and jacket are oil-resistant and

weather-resistant rated.

TPE Cable

- SEOW—Extra hard service cord, thermoplastic elastomer conductor insulation and jacket with oil-resistant jacket and weather-resistant rated.

- SJEOW—Hard service cord, thermoplastic elastomer insulation and jacket and weather-resistant rated.

Notes on the Above Cable Designations:

- Definitions of cable designations are derived from UL’s designation scheme as defined in the National Electric Code (NEC)—NFPA-70.

- When only one “O” appears in a classification (e.g. SJEOW), only the outer jacket material is oil-resistant. If two “O’s” are in the classification (e.g. SJEOOW), the insulation covering the conductors and the outer jacket insulation are both oil-resistant.

- CSA does not recognize the letter “E” used by UL to designate thermoplastic elastomer. CSA classifies these cable types using the PVC classification designations with a “TPE” suffix. For example, the designation SJTW (TPE) is used in Canada and SJEW is used in the United States.

See more information on North American cable types.

International Cable

A series of numbers and letters indicate the jacket material, ratings, and size of the cable. The types of international cable offered by Interpower include:

- H03VV-F

- H05V-K

- H05RN-F

- H05VV-F

- H07V-K

- H07RN-F

- RVV

- VCTF

- HVCTF

- S05VC4VF

The Harmonized Wire Coding System chart, found on Interpower’s website, gives more explanation about what the various letter and number designations mean.

Some Notes on International Cable:

- International cable needs to be manufactured in accordance with EN (European Norm) 50525 cable standards. These are European standards accepted by member countries of CENELEC (European Committee for Electrotechnical Standardization), an organization which has agreed upon formalized methods of construction and testing for common products.

- Manufacturers from countries outside of the CENELEC group can be awarded approval to make international cable. They need to have approvals from at least one of the European testing agencies in accordance with the EN 50525 standards. When listing a cable type, e.g. H05VV-F, the “H” means it meets the harmonized cable standard (EN 50525), except that it is manufactured outside the CENELEC group of countries.

- Some international cable carries a special marking—the <HAR> mark—but not all international cable does. Depending on where the cable manufacturer is located, determines whether the <HAR> mark can be put on the cable itself. The <HAR> mark is a common marking that can only be used on cable manufactured by signatory members of CENELEC.

- International cable needs to be manufactured in accordance with the IEC (International Electrotechnical Commission) cable standards, such as IEC 60227, and may also need to follow other country-specific cable standards as well, depending on the country the cable will be used in.

- International cable (depending on approvals) can be used in Europe and in other countries throughout the world—except in North America.

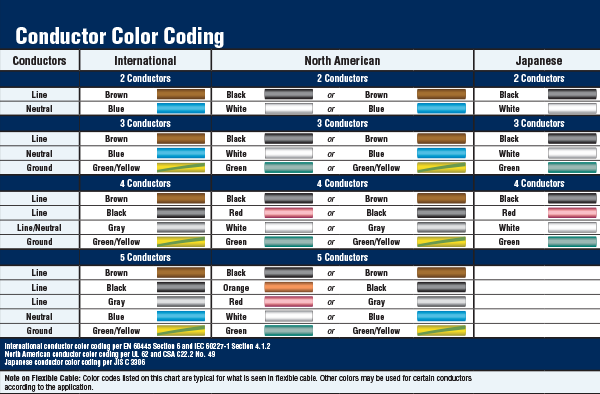

Conductor Color Coding

Marking of the conductors within the cable defines which conductor is ground, neutral, and line. There are different color codes for North American and international cable. For North American 3-wire cable, there are two color codes that are accepted and most widely used. The combination of green (ground), white (neutral) and black (line) is the North American cable color code. The international color code combination of green/yellow (ground), light blue (neutral), and brown (line) is also an accepted color code for North American 3-wire cable.

Testing and Certification Requirements

North American Cable

Interpower North American cable meets the UL and CSA standards.

International Cable

Interpower international cable is tested and certified according to international standards.

Cable Market and Safety Agency Strategy

The end destination will also determine which safety agency should be contacted to obtain approvals on the cable.

Determine the Market and the Safety Agency

To begin with, the manufacturer needs to decide on where the product will be marketed to. The market determines which approvals will need to be obtained, which in turn determines which safety agency a product should be submitted to.

Learn the Requirements of a Safety Agency

Sometimes one country will accept another safety agency’s testing results. An example would be submitting cable to VDE, a German safety agency. After testing, they will issue a report. If a manufacturer would also like approval from another safety agency, several other European safety agencies will accept the report from VDE and no further testing would need to be completed. It needs to be noted, however, that it depends a lot on the country or region. If the cable is to be submitted to China for approval, for example, testing will be required by a Chinese safety agency. Tests from other agencies are usually not accepted.

It is necessary to learn the requirements of the safety agency that a manufacturer will be submitting the cable to for approval. For example, an agency may require specific types of cable to be submitted for approval. Some agencies approve different cable types regardless of color, while others certify cable type size by a specific color. If an agency certifies by color that means all of the different colors would need to be submitted to that agency.

Interpower Manufactured Cable

Interpower manufactures the following North American cable types: SJT, SJTO, SJTW, SJTOW, and SVT. The sizes include 18AWG up to 12AWG. All are approved by UL and CSA. The cable is available in the conductor color codes of black (line), white (neutral), and also in brown (line), blue (neutral), and green/yellow (ground).

Interpower manufactures H05VV-F in sizes 0.75mm2 up to 2.50mm2. All of these sizes have approvals from VDE (Germany), Semko (Sweden), OVE (Austria), Dekra Kema-Keur (Netherlands), and Department of Fair Trading (Australia). Some sizes also have KC (Korea) and CCC (China) approvals. The cable is available in the conductor color codes of brown (line), blue (neutral), and green/yellow (ground).

Interpower also manufactures Japanese VCTF and HVCTF in sizes 0.75 mm2, 1.25 mm2, and 2.00 mm2. All of these sizes have PSE approval. The cable is available in the conductor color codes of black (line), white (neutral), and green (ground).

Additional Resources

For more specific information on Interpower manufactured cable, including value-added options, contact Customer Service. For more details on the complete line of North American and international cable offered by Interpower, including cable manufactured by Interpower, see North American and International Cable. See also the Featured Product pages on North American Cable and Interpower International Cable.

Interpower offers free technical support. For further assistance, please see Interpower’s contact information below.